Benefits of Shot Peening

Shot Peening

Shot Peening, also known as shot blasting, causes the material in the surface zone to yield by literally shaking the metal grains into a more relaxed state. As a result, the surface layer counteracts tensile stress and effectively prevents cracking. Blast Finishing and shot peening are state-of-the art technology that deburr, clean and enhance appearance. Shot peening can even improve the fatigue life of parts such as: gears, housings and shafts.

What are the benefits of shot peening?

Machining and forming metal parts creates stress concentrations internally (burns, scratches, welds, etc.) and can cause other additional defects.

These problems may be responsible for premature fatigue failure, porosity, deteriorated strength and corrosion, but can be prevented with shot peening.

Since fatigue cracks generally begin at surface imperfections, a compressively stressed peened skin is highly effective in preventing crack formation and growth.

In recent years, gears have been shot blasted after carburizing and have been made of steel at a hardness level above Rockwell 60RC for fatigue and shock applications. The figures below show the close connection between peened versus unpeened gears.

Contact Engineered Abrasives® today to learn more about our shot peening machines and shot peening services.

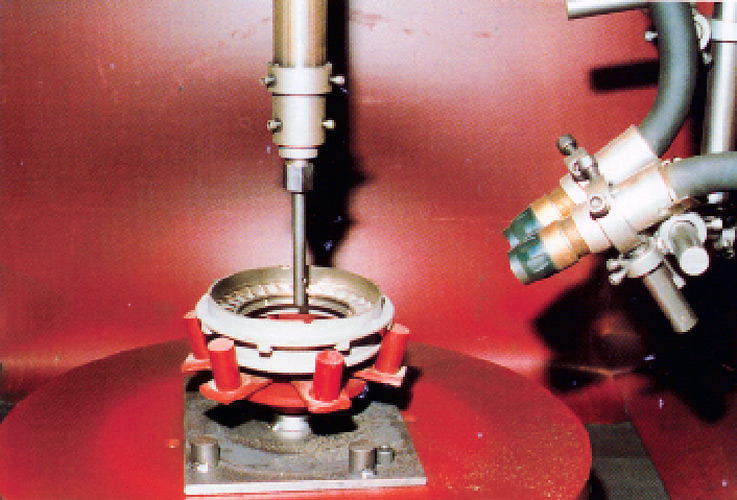

Look for RED components and surfaces to be sure you get Engineered Abrasives® quality equipment OEM parts.